INTERVIEW | テクノロジー / プロダクト

2025.10.14 10:09

The iPhone Air joins the iPhone lineup as an entirely new addition.

Apple’s unveiling of the new iPhone seemed as if it were running two divergent visions of the future side by side. On one hand, iPhone Air, a pursuit of extreme lightness and thinness; on the other, iPhone 17 Pro, a device that fully embodies the strength of a “tool.” By deliberately presenting these opposing directions simultaneously, Apple has returned to the fundamental question of how design shapes experience. Through this rare exclusive with Apple’s design team, the company’s evolving vision of a “product aesthetics” comes sharply into view.

The iPhone 17 Pro, equipped with the fastest chip and an AI-powered camera.

redefining the iPhone lineup

“We set out to redefine the Pro” At Apple’s latest iPhone launch event on September 10 (local time), Molly Anderson—who leads the Industrial Design team at Apple’s Design Studio—delivered these words in her British accent. While Apple kept the baseline iPhone 17 model largely unchanged in appearance (though with a larger screen), the company fundamentally reimagined the Pro series, beloved for its camera performance, and introduced an entirely new category: iPhone Air, distinguished by its striking thinness and elegance. At the launch, Anderson wore a vibrant navy PLEATS PLEASE ISSEY MIYAKE ensemble with a sky blue iPhone Air slung crossbody—a deliberate statement that Air is as much a fashion accessory as it is a phone.

We sat down with three key figures behind the new iPhone lineup: Molly Anderson, John Ternus (Senior Vice President of Hardware Engineering), and Alan Dye (Vice President of Human Interface Design).

The sky blue iPhone Air carried by Molly Anderson also marked the debut of Apple’s first genuine strap.

iPhone Air: Pursuing Thinness and Lightness

The thin, elegant iPhone Air and the robust iPhone 17 Pro/Pro Max present strikingly different characters.

“We work really hard to make the products feel great for everybody,” Anderson begins. “But I think you’re right to say the intention was to separate the feeling of the products. For the iPhone Air, it was absolutely about elegance and lightness. The way we polish the titanium—you get this very beautiful reflection from the mirror polish. And we chose predominantly lighter colors to evoke a feeling of lightness.

On the iPhone 17 Pro side, we thought about it much more as a tool. Making it even more durable, even more a professional device. What we love about the Cosmic Orange is that it’s a very strong color, but it’s also a very utilitarian color. So it’s bold, but it conveys the perspective that this phone is also a tool when you consider it in the context of International Orange, Safety Orange, and also how orange has been used by Apple — for example, the Action Button on Apple Watch; as accents on the Solo Knit Band for Apple Vision Pro; and on the Ring/Silent switch for the original iPhone.”

The iPhone 17 Pro in bold Cosmic Orange has been met with generally favorable reactions from consumers.

Anderson recalls that iPhone Air’s design discussion began with “thinness,” which evolved into pursuing both “thinness and lightness.” The goal, she explains, was to create something that “feels really like a piece of glass”—an echo of ISSEY MIYAKE’s pursuit of “a piece of cloth.”

“The core of the experience is about immersing yourself in the content, directly connecting with whatever you’re doing—whether you’re on a FaceTime call or looking at photos.”

Once that goal was established, the formal design process began in earnest.

“The way we work, the process the team goes through—we sit together and sketch, and then from those sketches we make models. From the models we get a sense of the product. Then collectively, we find something that’s special, that resonates with the team, and that’s where we set the target.”

It isn’t simply that “thinner is better”; in Apple products, thinness itself carries an aesthetic.

Continuing this iterative process, Anderson explains, “sometimes you get to a point where, the moment you hold something, it feels really magical. When we find that kind of goal we absolutely want to achieve, we share that conclusion and that feeling with our partners within the Design Studio and with hardware engineering. The desire to achieve that feeling drives much of the invention required to get there.”

What they arrived at for iPhone Air: “a form with a very expansive display, yet thin.” “I think you’ll be surprised when you pick it up. It’s a paradoxical sensation — it has a large 6.5-inch display, but is so surprisingly thin and light. And that’s what makes it feel magical and futuristic.”

Yet as Ternus explains, embodying this paradox proved challenging.

“Even with a product this thin, it must deliver exceptional battery life, outstanding performance, an expressive display, and a high-performance camera—all the functions and quality expected of an iPhone. Fitting all of that within the constraint of thinness was a significant challenge,” Ternus reflects.

They achieved this through critical decisions and Apple’s technical capabilities in chip development.

One of the most significant decisions: eliminating the physical SIM. While still used by many, the SIM card is an old mechanism that occupies considerable space merely to assign a phone number. Apple committed fully to eSIM—the emerging standard—thereby securing sufficient space within the device to meet specifications.

The shift to eSIM freed up internal space, allowing for a larger battery capacity.

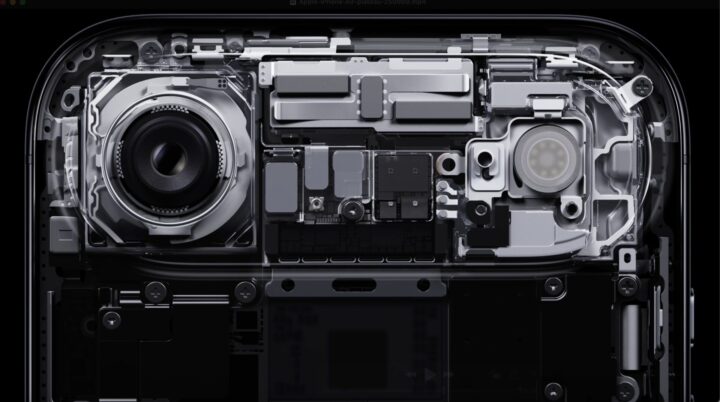

The iPhone’s camera system requires a thicker section, but Apple managed to fit all major circuit boards into the “plateau”—a horizontal ridge about the width of an ice cream spoon. This miniaturization was enabled not just by the A19 Pro processor but also by the C1X modem and N1 wireless chip—all compact, power-efficient components developed in-house, demonstrating Apple’s exceptional technical capabilities.

Housing the core circuitry within the plateau — Apple’s answer to ultra-thin design.

In iPhone Air, a bold design change places the battery, covered by ceramic shield, in almost all areas outside the plateau—enabling extended battery life despite a profile as thin as glass.

Plateau: A Design Language Connecting Hardware and Software

The plateau appears in the iPhone 17 Pro series as well. Anderson explains that the plateau, extending across the full width of the device, serves as an important commonality indicating that the iPhone Air and iPhone 17 Pro belong to the same family.

“What we really like is the balance of symmetry created by adopting the plateau. Through the iconic plateau extending across the entire product, we want people to feel the commonality between both products and clearly recognize them as a family. Another advantage: we can utilize the internal space created by having a plateau and put the components which are forward-facing in the center So there’s a balance of function and design elements coming together.”

The iPhone Air’s plateau, with its rounded ends resembling a water droplet, connects to something unexpected. “Please launch iOS and swipe down from the upper right corner,” Dye suggests. The gesture reveals a new software design with Liquid Glass—the latest iOS interface whose external appearance was prototyped in actual glass. The rounded button shapes mirror the plateau’s form exactly.

“At our Design Studio, hardware design extends beyond its boundaries to closely integrate with software design. We all work together in the same studio to design both hardware and software together.”

A presentation video of Liquid Glass by Alan Dye.

The plateau holds another surprise: despite the iPhone’s glass back, its contours are remarkably smooth—a form that competitors aimed for but found technically too difficult to achieve. What secret enabled Apple to achieve such sculpting?

“One factor is material science,” Anderson responds. “We use extremely durable materials to build our products. This is important not only from a reliability standpoint including drop durability, but it also enables us to create forms like this that weren’t possible before. It’s a significant breakthrough for us.” She continues, “It’s also one reason we haven’t done this before—we needed both the material science and the manufacturing capability. It takes considerable time in development, working very closely with our teams and the manufacturing design team to bring it all together.”

The plateau’s smooth contours embody Apple’s design philosophy and engineering skill—transforming constraint into beauty.

Ternus adds: “We have a specialized engineering team for manufacturing design. They focus not only on making parts accurately but also on researching and developing how to manufacture the parts. How do you create that beautiful curve and do it in a very consistent, very precise way? They’re a team of people who excel at such things. It’s a significant advantage to work with people like that. We have experts in many different disciplines, and that allows us to make parts like this.”

Anderson further notes that “if there’s something different about Apple’s manufacturing, it’s the attitude of never giving up on bringing wonderful ideas to life until we can realize them.” This sometimes manifests as innovation in the manufacturing methods themselves.

Balancing Environmental Responsibility and Quality

For example, in iPhone Air’s extremely tight space within that thin enclosure, to provide a precise and robust USB-C port, Apple employed 3D printing. This approach balanced strength and design while reducing material usage by 33%, Ternus explains. (The same technique is used for Apple Watch 11 titanium components.)

From an environmental perspective, utilizing recycled materials is equally important.

“Many years ago we started discussing using recycled materials across the board—paper, aluminum, and all other components including internals,” Anderson explains. “We’ve refined our techniques for creating aluminum alloys from recycled materials, and we’re proud that we’ve reached a level where it’s very difficult to distinguish between recycled and virgin materials. We wanted to ensure that even if products are made from recycled materials, they still feel like a special device.”

Ternus elaborates: “This isn’t just about appearance. When you use recycled material, you inevitably introduce some impurities that can affect not only appearance but also product performance—strength, thermal conductivity. So the alloys Apple creates, whether titanium or aluminum, are specially engineered so that even with a certain amount of impurities, they don’t affect appearance or performance. Actually, it took many years to achieve this.”

In environmentally conscious manufacturing, Apple leads competitors by a significant margin, and the accumulated knowledge has now reached a level that others cannot easily match.

Designing for Whom?

Throughout the interview, Apple’s user-first attitude was repeatedly expressed. We asked what kind of users Apple envisions when creating products.

“We don’t envision any one specific person,” Anderson responds. “Apple’s Design Studio creates everything from products to packaging with the entire team. Each team member has different experiences and expertise, and we’re an international team gathered from various countries around the world, engaging in symbiotic creation. So what we aim for isn’t a product that’s right for one specific person, but rather a product that’s right for a broad range of people. We know when we work together, create models, iterate repeatedly, and everyone picks up what we’ve made and feels a connection with it—then we know we’ve created something special.”

The iPhone launch event opened with Steve Jobs’s observation: “Design is not just what it looks like and feels like. Design is how it works.” After years of incremental changes, this event—introducing the most significant design transformation in iPhone history—felt like the resurgence of Apple as a design-driven company.![]()